100 feet of LEDs in a flexible poly casing is not very manageable. The LEDs need to point up (or down if hung from a ceiling) and not get twisted about. They also need a power line running along side them for power boosts every 15 feet or so. And finally, the Ethernet cable that carries the data from the far controller back to the main station needs to make the same traverse. I designed a simple cable management system that can hold the LED strip, power and Ethernet cable that I’ll be laser cutting a couple days from now.

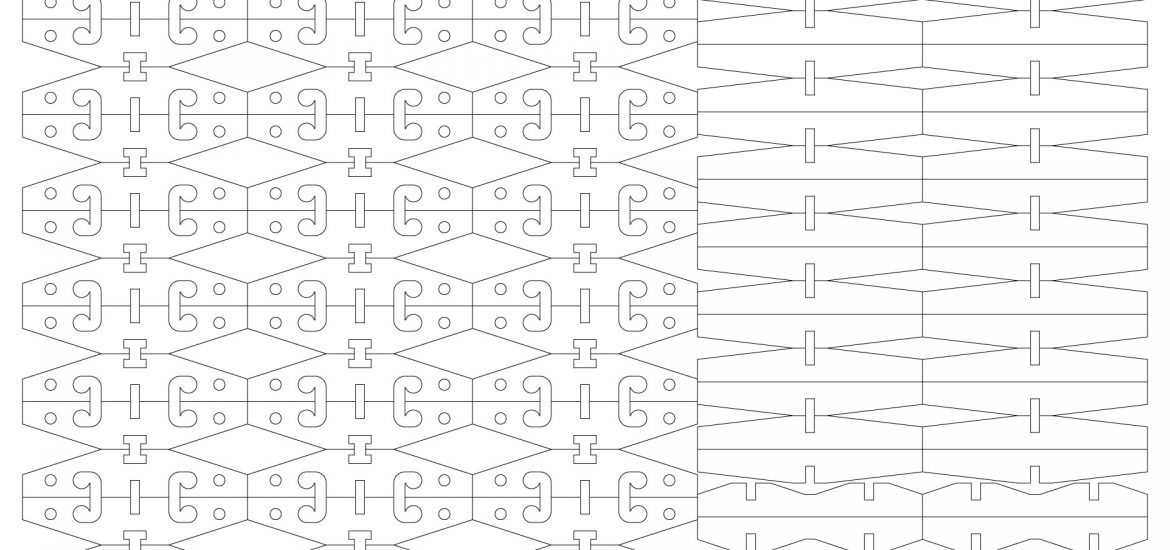

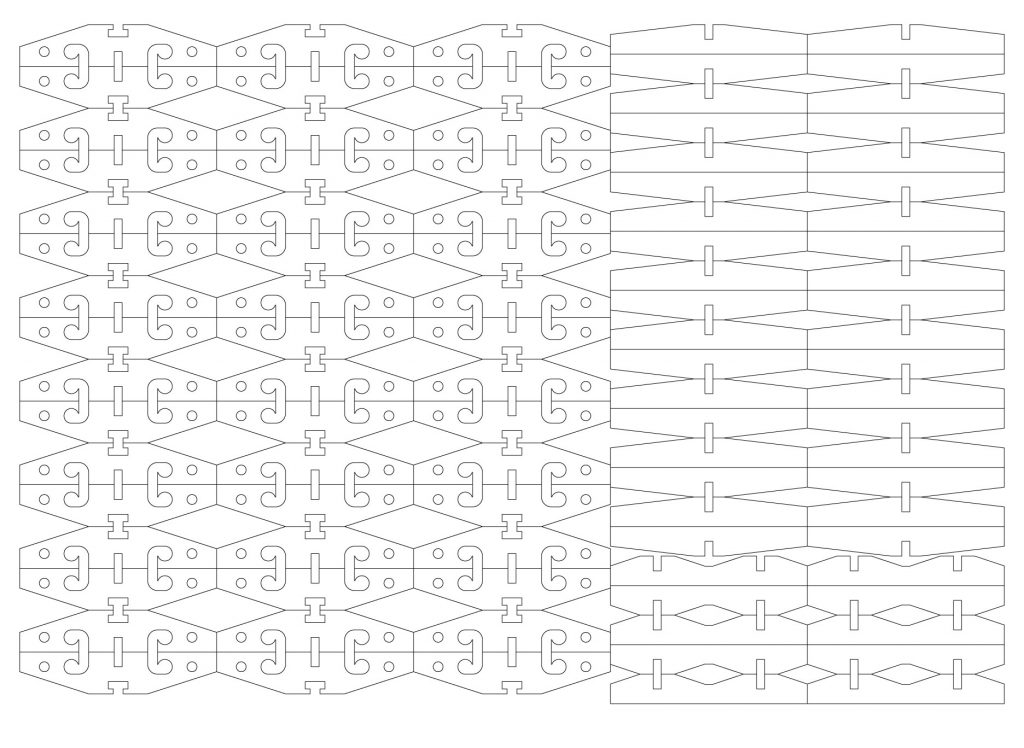

A simple cross of wood every meter with slots for the three lines is the plan. The pieces slot together so they can fit into a small box. It will make more sense when I take a picture of an assembly, but here’s the cutting plan for a 26″ x 19″ sheet of 0.2″ wood.

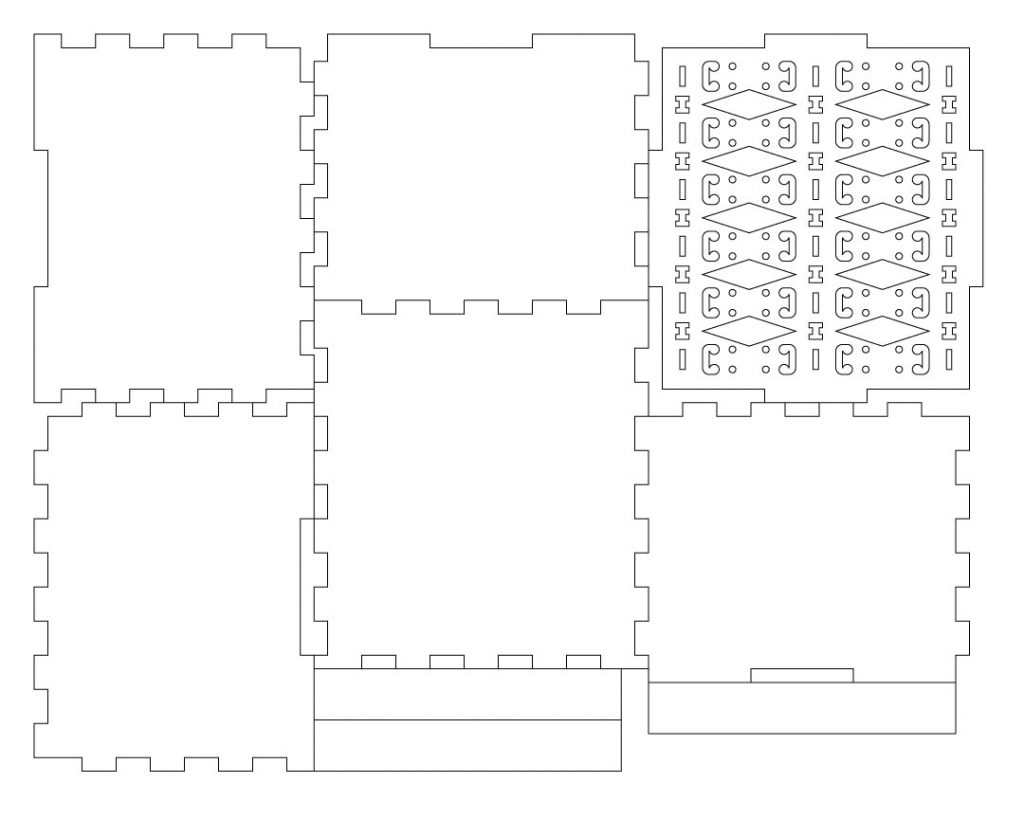

And the box to hold them in. The pattern on the top of the box is taken from the other cutting pattern.